Additive Manufacturing

2022 APR 6

Mains >

Science and Technology > Miscellaneous > Innovation and New technologies

WHY IN NEWS?

- Recently Ministry of Electronics and Information Technology (MeitY) has released a National Strategy For Additive Manufacturing (commonly known as 3D printing) to encourage collaboration between academia, government and industry with the goal of making India a global hub for design, development and deployment of 3D printing.

WHAT IS ADDITIVE MANUFACTURING?

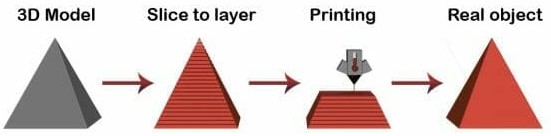

- Popularly known as 3D printing, Additive Manufacturing (AM) is defined as the technology that constructs a three-dimensional object from a digital 3D model by adding material layer by layer.

- The deposition and solidification are controlled by computer to create a three-dimensional object.

- The addition of material can happen in multiple ways. The common ways are:

- Material extrusion:

- Here, a filament of material is pushed through a heated nozzle, thereby melting it.

- The printer deposits the material on a platform along a predetermined path, where the filament cools and solidifies to form a solid object.

- Powder bed fusion:

- It is a 3D printing process where a thermal energy source (Eg: laser) will selectively melt and fuse powder particles (Eg: Metal powder) inside a build area to create a solid object.

- Vat polymerisation:

- In this process, a photopolymer is used as the raw material.

- A light source (like UV light) selectively cures the photopolymer resin in a vat, thereby creating a solid object. (A photopolymer is a polymer that changes its properties when exposed to light.)

- Most commonly used material in 3D printing are:

- Thermoplastic polymers: Acrylonitrile butadiene styrene (ABS), polycarbonate (PC) and polylactic acid (PLA).

- Metals: include precious metals like gold and silver to strategic metals like stainless steel and titanium.

- Bio materials: Eg: Stem cell tissues

- Ceramics

- Although it began as a quick and cheap way of developing prototypes, additive manufacturing has now gone mainstream in developed countries and is beginning to replace traditional manufacturing for many different applications.

- One recent survey of U.S. manufacturers shows that about 12% have started using additive manufacturing for their products and expectations are that this will result in about 25% of products in the next three-five years.

BENEFITS OF ADDITIVE MANUFACTURING:

- Reduces production cost and time:

- Conventionally manufactured part requires a number of processes like casting, forging, machining, drilling, and welding etc. whereas the same part can be produced by using AM in a single processing step.

- Create complex objects:

- 3D printing has the ability to print complex shapes and interlocking parts without the need for any form of assembly.

- This in turn helps in creating light-weight and more efficient parts.

- Minimal wastage:

- In the traditional manufacturing processes, based on subtractive techniques, the final product is manufactured through cutting or drilling an initial object, thus leading to a substantial loss of material.

- But in 3D printing, as the construction material is added layer after layer, the waste is almost zero.

- Customisation freedom:

- Traditional production methods relied on moulds and cutting and this makes customizing a very time-consuming process.

- As 3D printing is perfect for one-off productions and building single parts in one process, it offers the ability of customisation.

- Production on demand:

- 3D printing offers the ability to produce different objects a very small cost and in a short space of time, without the need for specific tooling for each object.

- This offers businesses a higher level of flexibility.

- Accessibility:

- The product’s digital design can be sent over the Internet and printed anywhere.

- There is already a large depository of ready-to-print designs available in the internet.

CHALLENGES:

- High initial investment:

- Since AM technology is still evolving, the equipment and material costs are high.

- In India, most of the industrial grade AM machines and raw materials need to be imported.

- Hence, the cost of setting up a AM unit is relatively high compared to conventional system.

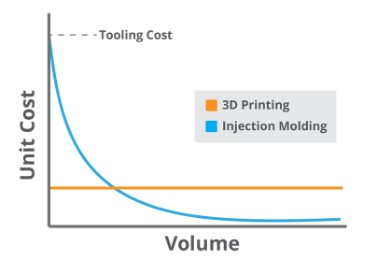

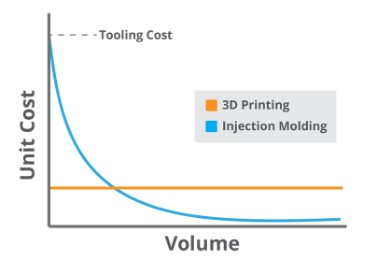

- Limited economies of scale:

- Unlike traditional manufacturing, the cost of production in 3D printing decreases nominally while printing a large number of objects.

- Durability and quality:

- Compared to conventional systems, items produced through 3D printing have a limited surface finish, consistencies in material properties and durability.

- Most of the objects need some post processing to before use.

- Absence of regulations and lack of standards:

- Since 3D printing is a very niche and new domain, there are no established industrial standards and certification norms on the processes or products in 3D printing.

- This makes it difficult to control the industry in matters such as quality, environmental safety, patent security, safety concerns etc.

- For example: without regulation, 3D printing can be used to print weapons or counterfeit parts.

- Technology intensive:

- The system is heavily dependent on computer systems and skilled manpower - from product design to printing.

- This not only pushes up the cost of production but also limits its application in developing countries like India.

- Issue of liability:

- AM could blur the lines between manufacturers and consumers as consumers themselves can manufacture goods for consumption.

- Laws and regulations, as they stand today, do not account for such a scenario and hence it may be difficult to fix liabilities in case of an error.

- Limited options on AM suitable materials:

- The type of materials that can be used for 3D printing are restricted to few types of plastics and metals.

- Promote unemployment:

- 3D printing requires few, but trained manpower to operate.

- Hence it can lead to unemployment, particularly in small and medium enterprises.

- Negative implications for developing nations:

- Additive manufacturing carries dangerous implications for developing nations.

- It decreases reliance on assembly workers and bypasses the global supply chain that has allowed countries like China to become prosperous through export of mass-produced items

- This may well lead to the creation of software-based design platforms in the West that distribute work orders to small manufacturing facilities, whether located in developed or developing countries, but ultimately transfer value creation towards software and design and away from physical manufacturing.

- This would imply that labour intensive manufacturing exports may be less profitable.

- Hesitation in adoption:

- Another challenge is to convince the industry and ministries to push for its adoption in their respective sectors as any new technology, which is not understood easily, faces a tough time.

APPLICATION:

- Prototyping:

- The first and by far the largest application of 3D printing technology is prototype development.

- Designers and engineers can save time and money by having their prototypes printed instead of machined.

- Industrial:

- Due to its ability to produce complex and light weight parts, AM is largely employed in the aerospace and defence industries.

- Besides them, automotive, electronics and consumer goods industries are also increasingly adopting 3D printing for tool making and spare parts productions.

- Healthcare:

- Bioprinting technology

- It can be used to create artificial living tissues that can mimic natural tissue characteristics.

- It has great potential for regenerative medicine

- Bioprinters could create cartilage, skin, and bone, as well as blood vessels and cardiac patches.

- Due to the geometric freedom afforded by AM, cost effectiveness and the ability to provide more personalised patient care, devices such as prosthetics and implants can be produced faster and more affordably than with traditional manufacturing methods.

- Education:

- Schools are incorporating 3D printing methods into their curriculums.

- It bridges the gap from ideas and images on a page, thereby enhancing the cognitive skills of youth.

- Construction:

- 3D printing applications are used in construction, like extrusion (concrete/cement, wax, foam, and polymers) and additive welding.

- Food industry:

- In the food sector, 3D printing is widely investigated across areas such as customized food designs and personalized nutrition.

- Recreational:

- With the advent of low-cost 3D printers, people have been using them for their personal recreation. Some of the more popular models created are artistic items, jewellery and toys.

INDIA AND ADDITIVE MANUFACTURING:

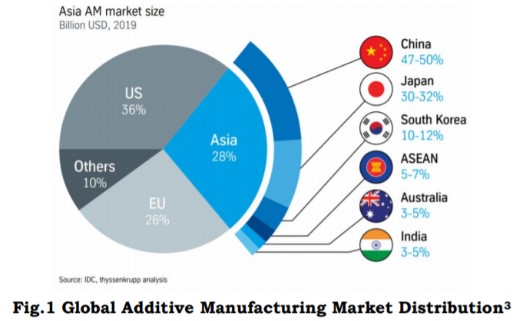

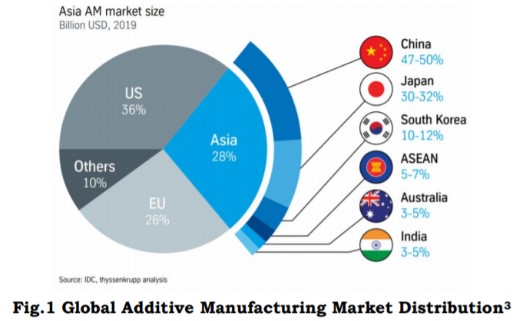

- In comparison to leaders such as the US and China, AM has not seen as much traction in India.

- However, it has generated considerable interest in the Indian academic and manufacturing ecosystem.

WHY INDIA SHOULD ENCOURAGE ADDITIVE MANUFACTURING?

- Facilitate ‘Atmanirbhar bharat’:

- Recent geopolitical and economic instabilities due to COVID-19 has exposed the fault lines in global supply chains.

- India can use this opportunity to proactively advocate self-reliance by developing strategies and roadmaps for adopting Advance Manufacturing technologies.

- Democratization of innovation:

- AM promotes democratization of innovation by empowering individuals to create and actively participate in the global value chain.

- This can benefit India’s MSME sector and young entrepreneurs.

- Encourages sustainable development:

- AM results in a considerable reduction in use of raw materials and also facilitates development of new materials and technologies which are more energy and resource efficient.

- These advantages would enable India to alleviate its carbon footprint and increases its energy security.

- Crisis management:

- During the COVID-19 crisis, 3D printing was used for creating specialised surgical instruments and medicals devices such as ventilators, nose swabs and face shields.

- AM aided construction can be used to quickly rebuild areas affected by disasters like cyclones and floods.

OPPORTUNITIES FOR INDIA:

- Eliminating large capital investments:

- Machines are cheaper, inventories can be small and space requirements are not large.

- Thus, jump-starting manufacturing does not face the massive hurdle of large capital requirement and the traditional small and medium enterprises can easily be adapted and retooled towards high technology manufacturing.

- Leveraging India’s IT power:

- The Indian software industry is well-established, and plans to increase connectivity are well underway as part of ‘Digital India’.

- This would allow for the creation of additive manufacturing facilities in small towns and foster industrial development outside of major cities.

- Uniform quality standards:

- Maintaining uniform product quality is far easier because the entire system is built at the same time and assembly is not required.

- Suited for tropical environment:

- It is possible to build products that are better suited for use in harsh environmental conditions.

- Products that required assembly of fewer parts also implies that they may be better able to withstand dust and moisture prevalent in our tropical environment and be more durable.

- Suited to our consumption-culture

- In a country where use-and-throw is an anathema, maintaining old products is far easier because parts can be manufactured as needed and product life-cycles can be expanded.

INITIATIVES

- National Strategy for Additive Manufacturing Policy, 2022

- The policy aims to increase India’s share in global additive manufacturing to 5% within the next three years and add USD 1 billion to the GDP.

- Further, it aims to develop 50 India specific technologies for material, machine and software, 100 new startups for additive manufacturing, 500 new products and train at least 1 lakh new skilled workers.

- The Policy postulate the tenets of ‘Make in India’ and ‘Atmanirbhar Bharat Abhiyan’ that advocate self-reliance through the technological transformation of the production paradigm.

- Atal Innovation Mission:

- Under the mission, Atal Tinkering Labs have been set up, where do-it-yourself (DIY) kits on technologies like 3D Printing are installed for school students to learn to create innovative solutions.

- As part of the programme, initiatives such as 3D design challenges were also launched.

- “Maker Village”:

- It is Government- Academia collaboration between MeitY, IIITM-K, Government of Kerala and Kerala Start-up Mission.

- The institute provides facilities for ideation of product development in Industrial 3d Printing and Plastics facility, among others.

- It also provides financial assistance and co investment opportunities.

- National Institute of Electronics & Information Technology, Aurangabad:

- The institute has established a 3D printing Manufacturing Lab and a certificate course in 3D Printing.

- Public-Private collaborations:

- Department of Heavy Industries has collaborated with Wipro to build India’s first industrial grade 3D printer.

- Stratasys has announced a collaboration with NTTF (Nettur Technical Training Foundation) to launch India’s first additive manufacturing certification course.

- 3D printing centres of Excellence:

- Various states have started to establish centers of excellence in collaboration with international institutions and industries.

- Example: Himachal Pradesh has signed an MoU with the Government of AP to build a Centre of Excellence for 3D printing.

- Private sector initiatives:

- “Addwize”: An additive technology Adoption & Acceleration programme by Wipro to encourage metal Additive Manufacturing (AM).

WAYFORWARD:

- Promotion of R&D:

- There is a need to accelerate research at our premier engineering schools on manufacturing machines and methods and encourage the formation of product design centers so that the products are built to suit the Indian environment and consumers.

- Need for Government Support:

- There is a need for government support to provide incentives for distributed manufacturing in smaller towns, and for the IT industry to work on creating platforms and marketplaces that connect consumer demands, product designers and manufacturers in a seamless way.

- A comprehensive national strategy on additive manufacturing:

- To position itself as a pioneer in additive manufacturing, India must create a necessary ecosystem.

- To attain this, a national strategy, which emphases on creating necessary regulations, skilled manpower, research ecosystem, Supply Chain Development etc is the need of the hour.

- Creation of a centralised facility:

- The creation of a centralised facility as a hub and the R&D domains as spokes in a consortium mode can be an effective model for the launch of a National Initiative for positioning India at the forefront of development and adoption of AM.

CONCLUSION:

- If ‘Make in India’ is to succeed, it needs to encompass ‘Make it the Indian Way’. It need not emulate mass production technologies, fuelled in Detroit by massive capital investment or in Beijing by cheap labour.

- We need to develop a manufacturing ecosystem that is adapted to additive manufacturing technologies.

- The potential of this technology is huge. To keep pace with rapid global manufacturing prowess, India needs to adopt an integrated approach to AM in all segments, including strategic and public sectors.

PRACTICE QUESTION:

Q. Analyse the potential of additive manufacturing technology? Examine the challenges faced by India in adopting additive manufacturing?