India's preparedness against Chemical Disasters

2020 MAY 9

Mains >

Disaster Management > Disasters > Disaster Management Act, 2005

IN NEWS:

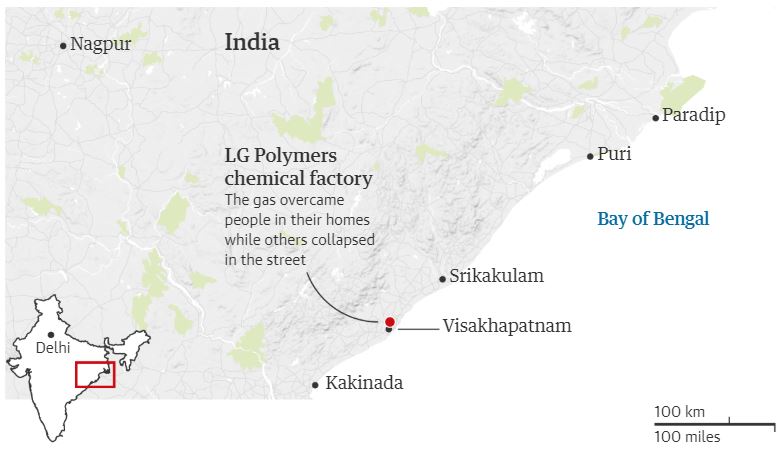

- At least 11 people have been killed by a massive Styrene gas leak at a chemical plant in southern India, with 800 others taken to hospital.

STYRENE GAS:

- Styrene, also known as ethenylbenzene, is an organic compound derived from benzene. It is a colorless oily liquid compound that evaporates easily and has a sweet smell.

- It is a flammable liquid that is used in the manufacturing of polystyrene plastics, fiberglass, rubber, and latex.

- Styrene is primarily a synthetic chemical. However, it is also found in vehicle exhaust, cigarette smoke, and in natural foods like cinnamon, coffee beans, and peanuts.

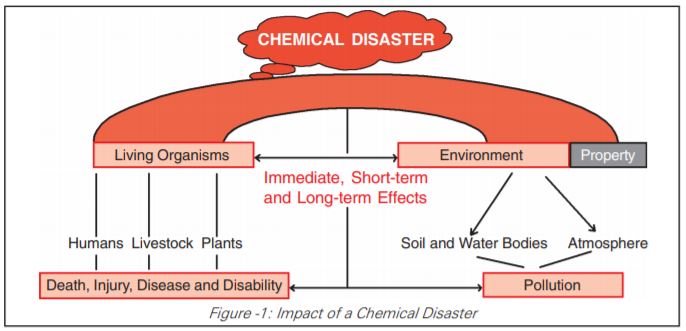

- Styrene is regarded as a ‘known carcinogen’. Short-term exposure to the substance can result in respiratory problems, irritation in the eyes, irritation in the nose, and gastrointestinal issues.

- Long-term exposure could affect the central nervous system and lead to other related problems like peripheral neuropathy. It could also lead to cancer and depression in some cases.

CAUSES FOR CHEMICAL DISASTERS:

- Process and safety systems failures arising from Human errors, Technical errors or Management errors, such as design defects, neglecting safety instructions poor emergency planning and coordination.

- Induced effect of natural calamities. E.g.: the release of acrylonitrile at Kandla Port, during an earthquake in 2001

- Accidents during the transportation

- Hazardous waste processing/ disposal

- Terrorist attack/ unrest leading to sabotage

CHEMICAL DISASTER RISK IN INDIA:

- India has witnessed the world’s worst chemical (industrial) disaster ‘Bhopal Gas Tragedy’ in 1984, where over thousands of people died due to accidental release of toxic gas Methyl Iso Cyanate (MIC).

- There are over 1861 Major Accident Hazard (MAH) units spread across 301 districts and 25 states and three Union Territories. Further, there are thousands of registered and hazardous factories and unorganised sectors dealing with numerous ranges of hazardous chemicals.

- According to the National Disaster Management Authority (NDMA), in the recent past, over 130 significant chemical accidents have been reported in the country, which have resulted in 259 deaths and caused major injuries to more than 560 people.

SAFETY INITIATIVES TAKEN IN INDIA:

- At the time of the Bhopal gas tragedy, the Indian Penal Code (IPC) was the only relevant law specifying criminal liability for such incidents. Soon after the tragedy, the government reformed the laws, regulating the environment and prescribing and specifying safeguards and penalties.

- The relevant provisions on chemical disaster management prevailing in country are covered under:

- Explosives Act, 1884

- Petroleum Act, 1934

- Factories Act, 1948

- Insecticides Act, 1968

- Environment Protection Act, 1986

- Motor Vehicles Act, 1988

- Public Liability Insurance Act, 1991

- Disaster Management Act, 2005

- Manufacture, Storage and Import of Hazardous Chemicals (MSIHC) Rules, 1989

- Chemical Accidents (Emergency planning, Preparedness, and Response) Rules, 1996

NDMA GUIDELINES:

- The guidelines, to be incorporated in the national and state-level chemical and industrial disaster management plans, focus on industrial installations, transportation, pipelines, cryogenics and storage of hazardous chemical compounds. Some of these are as follows:

- Management of Chemical Disasters:

- Guidelines to strengthen the present regulatory framework, which promote self-regulation and public consultation are required.

- The guidelines spell out a key role for local administration. This includes strengthening mechanisms for accurate, timely dissemination of warnings, GIS-based technologies and ensuring testing of emergency plans through mock exercises, besides creating awareness and education.

- Preparedness:

- Regular educational programmes in the form of symposia, exhibitions and demonstrations shall be encouraged.

- The state should formulate new and review existing regulatory framework and establish Codes of Practices, Procedures and Standards.

- Strengthen medical preparedness including creation of trained medical first responders, facilities for fast detection and decontamination, mobile hospitals/mobile teams and hospital disaster management plans need to be strengthened.

- Role of Industry:

- Industrial units using hazardous chemicals should undertake Chemical risk assessment and have onsite and offsite emergency plans in place.

- Periodic safety audits & mock drills: Periodical assessment of safety procedures and practices, performance of safety systems and gadgets should be carried out.

- Dedicated manpower and infrastructure should be created to prevent and mitigate chemical disasters at all levels.

- Employees should be made aware and trained to deal with potential safety hazards.

- Industries should share resources and enter into mutual aid agreements.

- Regular educational programmes in the form of symposia, exhibitions and demonstrations should be encouraged.

- Role of People:

- Critical management teams at various levels responsible for community awareness need to be created.

- Community members should be involved in the identification of high risk areas, formulation of disaster management plans and in capacity building measures.

- It also covers disasters that can occur during transportation of hazardous chemicals on highways or through pipelines. For transportation disasters, the NDMA recommends the promotion of transportation emergency management by development of highway disaster management plans and a pipeline management system.

WAY FORWARD:

- Strict enforcement of laws and regulations: The recurring industrial accidents in recent past highlighting the gaps present in the safety legislations and rules in India. Though a profusion of laws exists to protect workers, few are enforced.

- Strengthen criminal justice system: Workers or their relatives, who are mostly migrants, are unaware of their rights or have the resources to seek legal redress. The criminal justice system in India is slow, which aids the violators to escape.

- Strong political will: To ensure an attractive environment for business, the governments are easing the labour and industrial laws. This has increased the vulnerability to disasters.

- Standardizing: The safety laws and reporting mechanisms should be upgraded and standardized in accordance with globally recognized levels. These should be implemented with the help of technically competent authorities and a reliable enforcement mechanism. For it to become a reality, the government has to initiate amendments to chemical accident rules, so as to minimise disasters such as the one that happened at Visakhapatnam.

PRACTICE QUESTION:

Q. Though a profusion of laws exists to protect workers, chemical accidents have become a recurring event in India. What are the causes for such accidents? What measures should be taken to prevent such accidents?